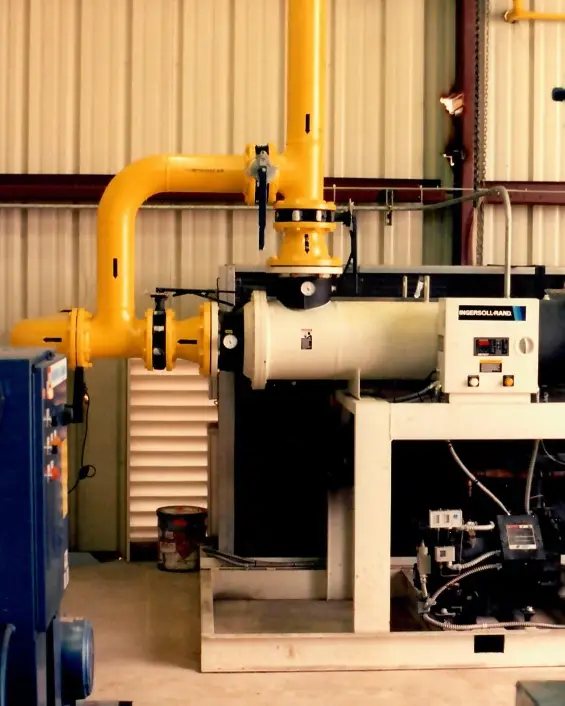

When it comes to piping systems, one thing is true; no two systems are the same. Every company’s facility is different, their equipment is different, and their specifications are different.

That’s why every piping system must be engineered from the ground up, considering diameter, piping material, pressure, temperature and the fluid or gas to be transported. Our engineers can help you design and plan your system, while our fitters will complete the best installation possible.

We’ll recommend piping materials based on your specific application needs and can consider:

- Carbon Steel

- Galvanized Steel

- Stainless Steel

- Copper

- Aluminum

- Plastics

Carbon and Galvanized Steel

Because of its strength, availability and affordability, steel is by far the most common piping material for commercial and industrial projects. These pipes can be joined in multiple ways, depending upon the pressure and temperature requirements of your projects. Steel pipes can be joined by threading, grooving, pressing, welding or in combination of these methods to give you the best results throughout the system.

Galvanized steel is coated with zinc. This coating adds corrosion protection to the carbon steel, complementing its existing strength, availability and affordability.

Stainless Steel

The superior corrosion resistance of stainless steel is worth the extra cost investment when needed for high purity food grade and pharmaceutical applications. Strong and widely available, stainless steel can be joined by threading, grooving, pressing and welding.

Copper

Less costly and more available than stainless steel, copper piping is more resistant to corrosion than carbon steel, but less so than stainless steel. Suitable for many compressed air, inert gas and water applications, copper is easy to install and can be joined by soldering, brazing, grooving and press fitting.

Aluminum

The lightest of metal piping materials, aluminum is your preferred material where weight is a critical factor. With proper coating, aluminum provides quality corrosion resistance, but does not have the structural strength of steel. Aluminum systems are easier to handle and install and faster to assemble than other materials. This metal is most commonly joined by grooving, press fitting and welding.

Plastics

Depending upon your needs and applications, plastic piping may be your answer. Plastic is available in PVC (polyvinyl choloride), CPVC (chlorinated polyvinyl chloride), polyethylene and other compounds.

PVC

Readily available, affordable and easy to install, PVC piping does not corrode. It is suitable for water and non-hazardous liquids, but cannot carry compressed air or other gases, due to limitations on pressure and temperature.

PVC is easily joined by liquid cement technologies.

CPVC

With similar advantages to PVC, CPVC can be used at higher temperatures.

Polyethylene

Polyethylene is flexible and lightweight, a solid choice for underground natural gas, in-floor heating and compressed air applications. Polyethylene is the easiest and fastest to assemble of all piping materials, joined by press fittings and plastic welding techniques.

When you are ready to design and install your piping system, call Apex Mechanical & Electrical for a turnkey solution. Schedule a consultation today by calling 708-930-7800.

Photo Gallery