Systems used to prepare edibles and potables are in a special category – and our team understands that, having decades of experience designing and installing equipment within food & beverage facilities.

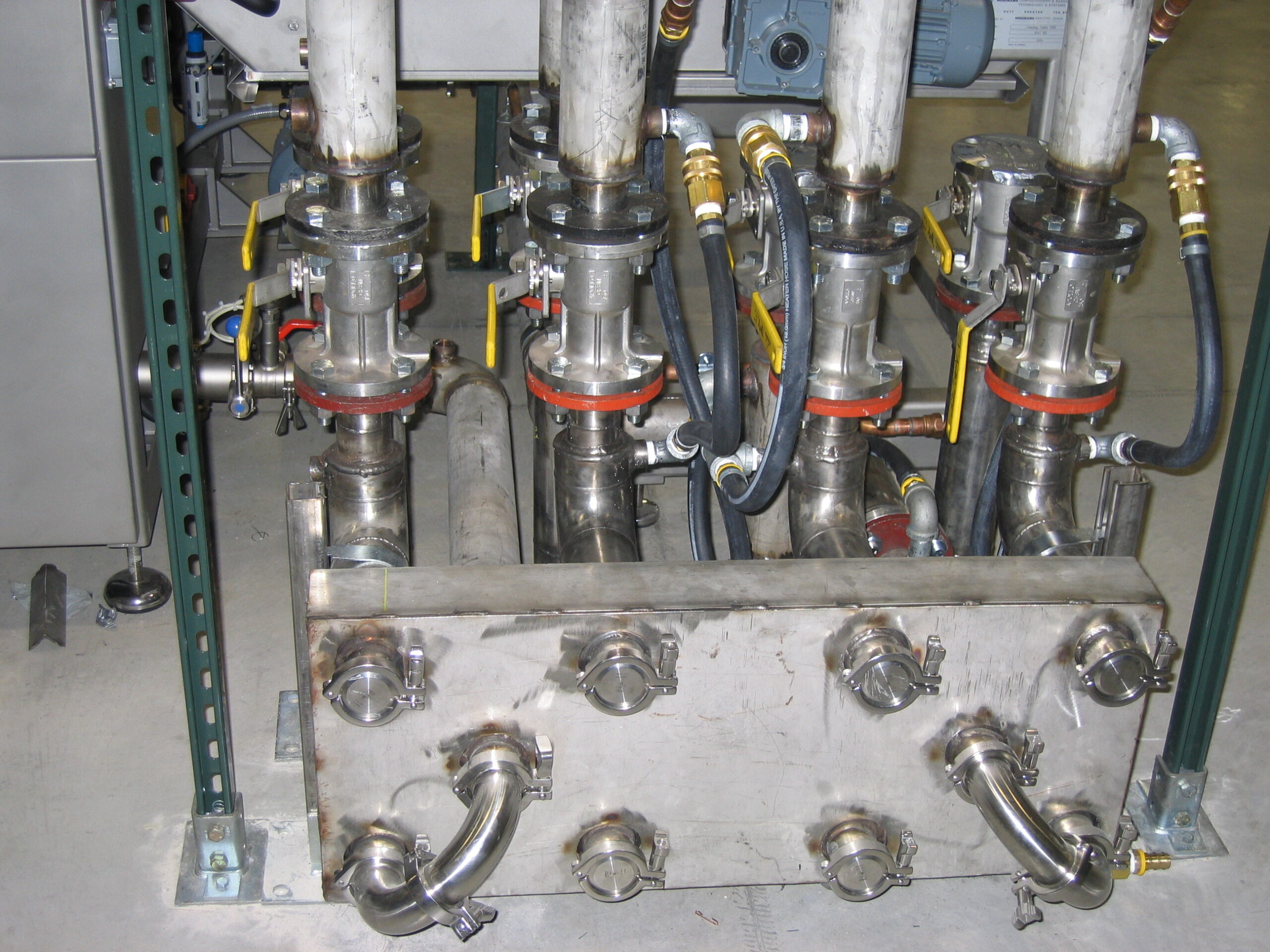

We’ll recommend the best quality and highest functioning piping materials, typically made of 304 or 316 stainless steel and conforming to 3-A Sanitary Standards. These pipes must be non-contaminating and perfectly smooth, able to be thoroughly sanitized often. There can be no crevices to hide bacteria, so they are usually joined with specialty stainless steel clamping fittings, or welded with Metal Inert Gas (MIG), (Tungsten Inert Gas) TIG or orbital welding methods.

Food products such as chocolate and fats must be kept liquid, to flow freely. Apex Mechanical & Electrical are experts at installing systems that allow warm watering jacketing on the outside of the piping, requiring MIG and TIG welding.

The professionals at Apex Mechanical & Electrical thoroughly understands the particular needs of the food & beverage industry, having worked with a major Chicago chocolatier and other food industry leaders for decades. Call Apex Mechanical & Electrical today at 708-930-7800 to discuss how we can provide a turnkey solution for your unique project.